Cables for use in nuclear power plants will be safer and last longer

Zlín, 3 September 2024 – Develop power and communication cables that are applicable for the refurbishment or construction of new nuclear power plant units: This is the main goal of the project, which is managed by scientists from the Centre of Polymer Systems (CPS) at Tomas Bata University (TBU) in Zlín along with PRAKAB Pražská Kabelovna and the Institute of Nuclear Research in ŘEŽ. The Technology Agency of the Czech Republic (CR; Technologická agentura České republiky) acts as the granting authority.

The novel cables being developed must be radiation resistant while meeting the requirements to ensure safety and maintain functionality in the event of accidents in nuclear power plants involving loss of coolant and also in the event of fire.

“Cable manufacturers are required to respond to new legislative regulations and market requirements, where they need to guarantee that new electrical cables installed in nuclear power plants have an extended lifetime of up to 60 years and at the same time they meet strict burn limits without the use of halogen retardants,” explains Prof. Tomáš Sedláček as the supervisor of the Polymer Processing Research Group.

Actually, halogen retardants are highly toxic, as their combustion releases not only halogens but also halogen hydrocarbons, i.e. hydrochloric acid in the case of chlorine, which endanger persons found near any fire. The longer cable life also logically eliminates the costs associated with more frequent cable replacement and the risks associated with this. “These cables must meet the stringent requirement of a loss-of-coolant accident (LOCA), in which the cable is exposed to significant radiation, high pressure and temperature while making sure that the cable stays functional both during and after the accident,” adds researcher Tomáš Plachý, who is working within the project.

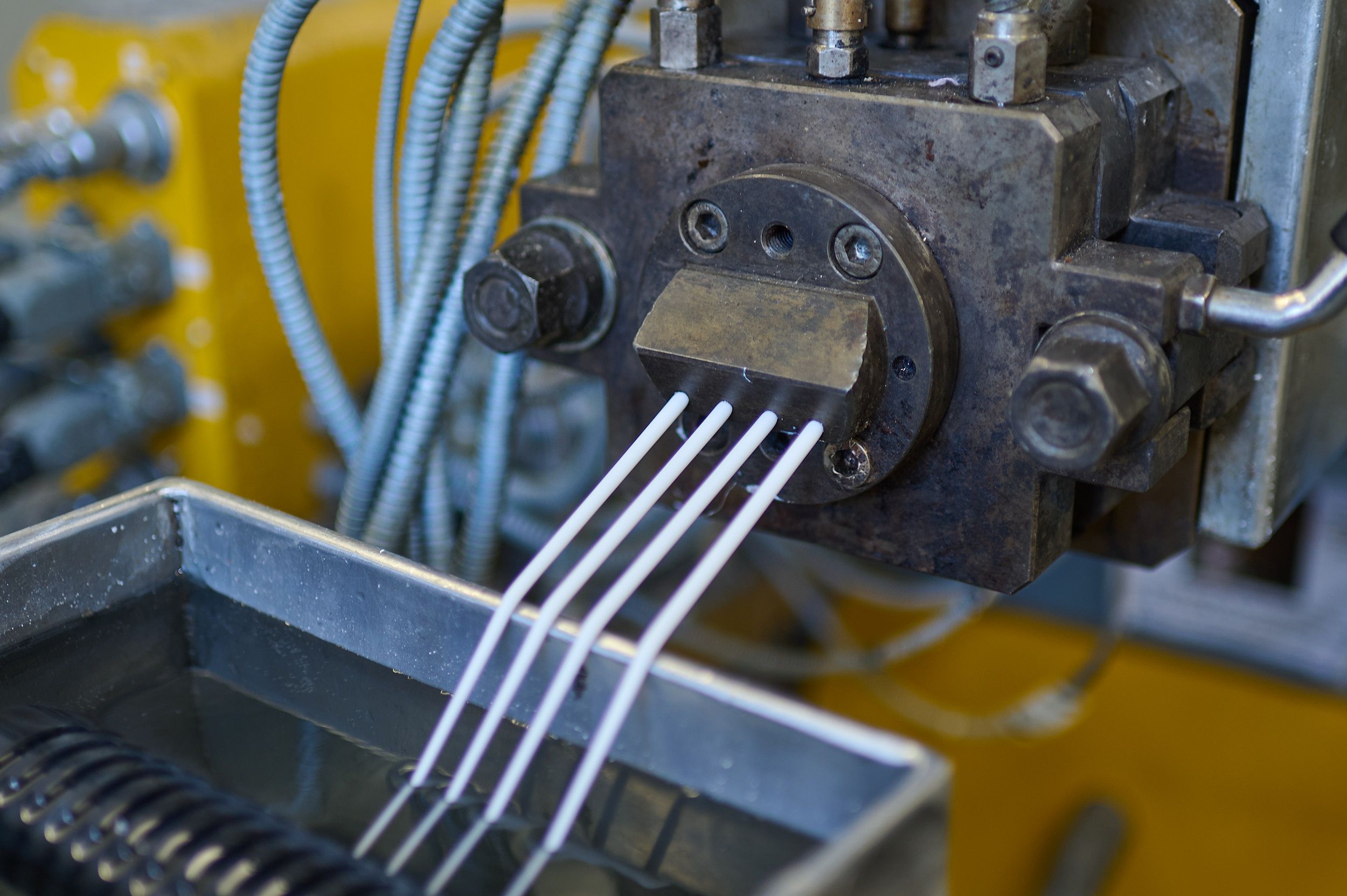

Scientists from the Polymer Processing Group of the Centre of Polymer Systems are involved in optimising the compositions being designed while drafting appropriate processing conditions with respect to the instrumentation infrastructure at PRAKAB.

“At the moment, suitable compounds have already been selected, which meet the basic requirements from mechanical properties, through the conditions of cross-linking of extruded samples during production on our technological lines up to the behaviour of materials after their ageing, and are further optimised to meet all the required requirements placed on these electrical cables, such as dielectric strength, mechanical properties, resistance to environmental influences, reaction to fire, functionality in case of fire and others," adds Pavel Šinka, Director of Technical Development at PRAKAB.

The expected project outcomes are electrical cables that meet the conditions for the Czech market and with respect to the conditions of the planned reactors that are envisaged to be exposed, as well as a system for foreign markets where specific conditions may be imposed on these cables due to different reactor types. The project is planned to be completed by the end of 2025; subsequently, the results will be implemented in the field by offering new types of cables to customers that show interest and potentially starting serial production.