How to make the most of plastic waste: new technology can also handle sludge

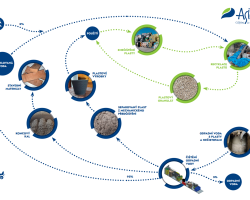

One of the many important projects in which the Centre of Polymer Systems is involved is the PolyEnvi21: National Centre of Competence in Polymer Materials and Technologies for the 21st Century project, which has a total of 20 sub-projects focusing on microplastics and the circular economy. The first of the sub-projects, focusing on technologies for the treatment of waste sludge from the mechanical recycling of flexible plastic packaging, has already been successfully completed. The main objective was to design and validate technologies for the separation of waste sludges containing plastics, which are generated during the sorting and washing of plastic waste, and to find ways to reuse them as by-products. In this way, the project contributes significantly to increasing the economic and environmental efficiency of the recycling process on sorting lines.

„Sustainability and circular economy principles are not just modern concepts - they are a necessary framework for how we approach materials, waste and energy resources. This project shows that even residual materials, such as waste sludge from plastics recycling, can be given a new meaning," said the project leader of the PolyEnvi21 project, Prof. Vladimír Sedlařík.

The optimised treatment processes take into account the efficient management of sludge waste with significant residual plastic content, thereby further contributing to the sustainability of the entire system. The final sorted plastic sludge materials have a high potential for further processing, especially in the production of plastic products for external technical applications. In addition to the proven technology for processing the plastics separated from the waste sludge of the sorting lines, three functional samples are the output. The first functional sample is based on separated plastics from sorting line waste sludge with optimised material properties for downstream production, the second is aimed at creating a material for solid alternative fuels and the third at a material for catalytic mineralisation. The developed technology and functional samples represent innovative solutions to reduce the environmental footprint of plastic waste.

The main solver of the project was ASIO TECH, spol. s r.o. The co-investigators were, in addition to the Centre of Polymer Systems, University of Technology Brno, University of Chemical Technology in Prague, Fortemix produkce, s.r.o. and ZODPA, s.r.o.