CHIP&CUT Analyzer

DEVICE IS FOR:

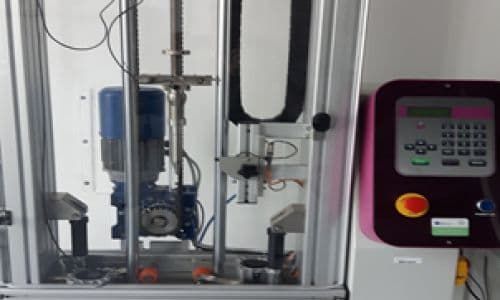

The device is used to characterize dynamic, fatigue as well as quasi-static rubber abrasion with dynamic forces in the variable frequency load band. Dynamic forces are derived in two perpendicular directions for characterizing both normal and frictional forces

The measuring principle of the device is based on the rotating test body of the variable geometry in the required range with dynamic forces being exerted by the linear drive in the normal direction to the rotating test body while maintaining the constant load force in the normal direction according to a given value overa defined load cycle time

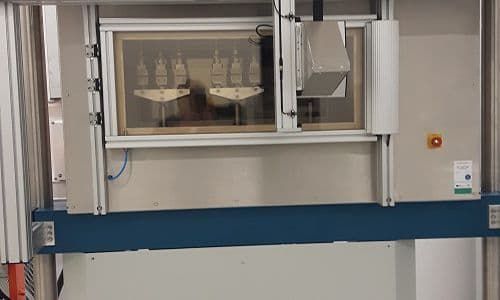

The device mainly serves to describe the dynamic abrasion known as Chip & Cut occurring in heavy-duty truck tires, as well as quasi-static abrasion to determine the coefficient of friction

Basic device parameters:

Realizable Load Modes: Dynamic Cycle Scraping and Quasi-Static - Permanent Scruff

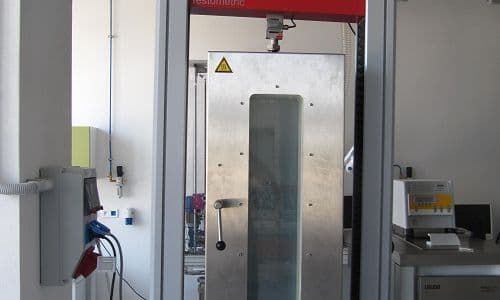

Speed range freely selectable in the range of 100

1400 rpm with 1 rpm accuracy

Measuring range of normal force ± 500N, - measuring range of normal force ± 900N,

Load frequency up to 10 Hz

Minimum penetration time and dynamic abrasion adjustable in the range from 20 ms

CONTACT:

MECHANICAL PROPERTIES