Equipment

- Hits: 2875

Zaměstnanecká příručka - aktualizace říjen 2025

Zaměstnanecká příručka - aktualizace červenec 2025

Zaměstnanecká příručka - aktualizace únor 2025

Zaměstnanecká příručka - aktualizace říjen 2024

Zaměstnanecká příručka - aktualizace září 2024

Zaměstnanecká příručka - aktualizace květen 2024

Zaměstnanecká příručka - aktualizace únor 2024

Read more …Zaměstnanecká příručka

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Komunikační plán 2025

Komunikační plán 2024

Komunikační plán 2023

Komunikační plán 2022

ECHC dotazník_Plastko

Vyhodnocení dotazníku slovně

Vyhodnocení dotazníku graficky

Aktuální stav SPLNĚNO

PŘ/02/2025 - Hodnocení a řízení rozvoje pedagogických, tvůrčích, řídících a dalších činností akademických a vědeckých pracovníků Univerzitního institutu Univerzity Tomáše Bati ve Zlíně

Aktuální stav SPLNĚNO

SŘ/02/2023 Pravidla a postupy pro obsazovaní pracovnich pozic vědeckých pracovníků na UNI

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

SŘ/02/2023 Pravidla a postupy pro obsazovaní pracovních pozic vědeckých pracovníků na UNI

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Plán školení

Nabídka školení 2024

Nabídka školení 2023

Nabídka školení 2022

Strategie rozvoje lidských zdrojů UTB

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Welcome Day - postup

Aktuální stav SPLNĚNO

Individuální adaptační plán

Aktuální stav SPLNĚNO

HRS4R plán

Aktuální stav SPLNĚNO

SŘ/02/2025 Směrnice ředitele – Pravidla pro stanovení OO a odměn

Aktuální stav PROBÍHÁ

Aktuální stav SPLNĚNO

Aktuální stav SPLNĚNO

Volební řád Akademického senátu UTB

Aktuální stav PROBÍHÁ

Read more …Implementace akčního plánu

EC Consensus Report – Implementation Phase Interim Assessment

Interim Assessment Report HRA

Comments

EC Consensus Report – Implementation Phase Interim Assessment

HR EC Consensus Report

Read more …Vnitřní hodnocení hra, vnější hodnocení hra

Prezentace ze setkání zaměstnanců CPS, prosinec 2018

Prezentace ze setkání zaměstnanců CPS, prosinec 2019

Prezentace ze setkání zaměstnanců CPS, prosinec 2020

Prezentace ze setkání zaměstnanců CPS, červen 2021

Prezentace ze setkání zaměstnanců CPS, prosinec 2021

Prezentace ze setkání zaměstnanců CPS, srpen 2022

Prezentace ze setkání zaměstnanců CPS, červen 2023

Read more …Setkání zaměstnanců CPS

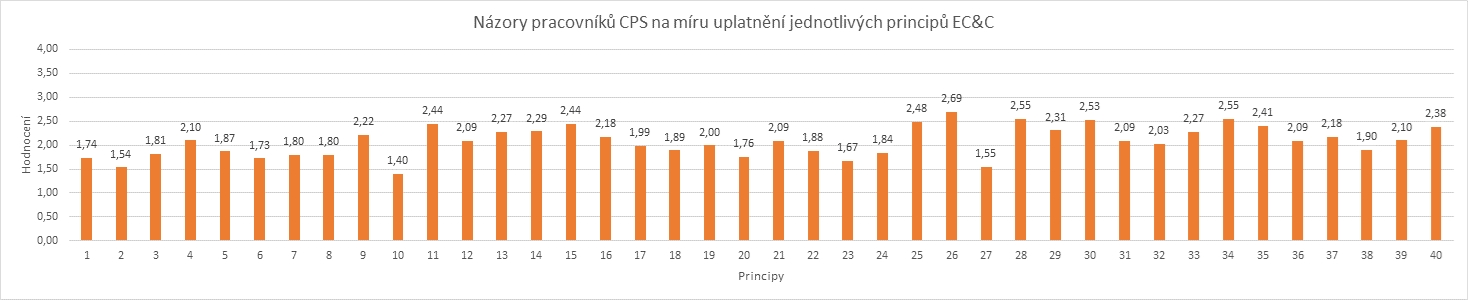

1. GAP analýza

Zpracování návrhu HRS4R vychází z analýzy současného stavu

uplatnění principů EC&C v podmínkách CPS a identifikace slabých míst (GAP analýza). Při analýze byly použity tyto metody: analýza textu Evropské charty pro výzkumné pracovníky a Kodexu chování pro přijímání výzkumných pracovníků (ECH&C), analýza národní legislativy vztahující se k etickému chování výzkumné organizace, analýza řídicích norem vztahujících se k etickému chování pracovníků UTB, analýza řídicích norem vztahujících se k etickému chování pracovníků CPS, rešerše „best practices“ vztahujících se k etickému chování pracovníků a manažerů výzkumné organizace ve vybraných zemích EU, analýza názorů pracovníků a manažerů CPS na míru uplatnění jednotlivých principů EC&C v prostředí CPS UTB.

Analýza názorů pracovníků a manažerů CPS na míru uplatnění jednotlivých principů EC&C byla provedena pomocí dotazníkového šetření. Dotazník zahrnoval celkem 40 principů, které stanovuje EC&C jako obecné zásady a požadavky upřesňující úlohu odpovědnosti a práva výzkumných pracovníků, managementu, jejich zaměstnavatelů a investorů. V jednotlivých položkách dotazníku respondenti ohodnotili míru uplatnění daného principu v podmínkách svého pracoviště. Čtyřicet principů EC&C je v dotazníku rozděleno do čtyř skupin: A. Etické a profesionální aspekty, B. Nábor pracovníků, C. Pracovní podmínky a sociální zabezpečení, D. Vzdělávání a školení.

Dotazníkového šetření se zúčastnili všichni výzkumní pracovníci CPS, všichni vedoucí výzkumných skupin, všichni manažeři CPS. Mezi respondenty byla zařazena i skupina externích partnerů CPS, abychom získali názory respondentů, kteří vzhledem k těsné spolupráci mohou vnitřní prostředí CPS posoudit pohledem z venku. Externí partneři byli managementem CPS vybráni tak, aby byly zastoupeny firmy ze Zlínského kraje i celé České republiky, ryze české firmy i firmy se zahraničním kapitálem, firmy od malých až po velké, a firmy s různou četností dosavadní spolupráce.

GAP analýza (souhrn jednotlivých kroků)

2. Akční plán

Pro vytvoření návrhů na opatření a zpracování akčního plánu realizace navržených opatření ke změně řízení lidských zdrojů v souladu s principy EC&C byla zvolena metoda Focus Group (FG). Byly vytvořeny 3 skupiny účastníků FG, v nichž byli zastoupeni výzkumní pracovníci CPS, vedoucí výzkumných skupin CPS, manažeři CPS, externí partneři CPS.

V úvodu jednání FG byli účastníci seznámeni s výsledky GAP analýzy a formou řízené diskuse navrhovali opatření k eliminaci slabých míst v uplatnění principů EC&C v podmínkách CPS. Diskuse směřovala k formulaci relevantních opatření pro krátkodobý (1 rok) a dlouhodobý časový horizont realizace.

3. Odeslání GAP analýzy a Akčního plánu na Evropskou komisi 21. 11. 2018

GAP analýza a Akční plán v podobě předepsaných šablon byly odeslány Evropské komisi k vyhodnocení.

4. Získání HR Excellence in Research award v březnu 2019.

5. Vnitřní hodnocení gap analýzy a plnění opatření akčního plánu

Zpráva o vnitřním hodnocení gap analýzy, o plnění a aktualizaci opatření akčního plánu byla 23. 2. 2021 odeslána na EK.

6. Zpráva hodnotitelů EK, Implementation Phase Interim Assessment – EC Consensus Report.

Zpráva hodnotitelů Evropské komise (EC Consensus Report), která hodnotí postup v první etapě implementace HRS4R a držení certifikátu HR Excellence in Research award, přišla na UNI/CPS přes e-tool na portálu Euraxess dne 18. 5. 2021. Hodnocení EK je pozitivní, bez připomínek. UNI/CPS pokračuje v držení HR Excellence in Research award a v realizaci Akčního plánu pro implementaci HRS4R. Termín obhajoby HR HR Excellence in Research Award (externí hodnocení EK) je za tři roky, tj. 05/2024.

7. obhajoba HR Excellence in Research Award (externí hodnocení EK).

Byl připraven Internal Review for Renewal Assessment a odeslán e-tool Euraxess. Site visit proběhne 22. 09. 2025.

1. Process Description_EURAXESS_HRS4R

2. GAP Analysis_ EURAXESS_HRS4R

3. OTM-R_ EURAXESS_HRS4R

4. Action Plan_ EURAXESS_HRS4R

Comments-EURAXESS_HRS4R

Legenda ke grafu Názory pracovníků CPS na míru uplatnění jednotlivých principů EC&C.

Pro vyjádření názoru použili respondenti čtyřbodovou hodnotící škálu 1 až 4, kde: 1 = princip plně uplatněn, 2 = princip skoro, ale ne plně uplatněn, 3 = princip částečně uplatněn, 4 = princip nedostatečně uplatněn.

Jednotlivé položky:

1. Svoboda výzkumu

2. Etické zásady

3. Profesní odpovědnost

4. Profesní přístup

5. Smluvní a zákonné povinnosti

6. Odpovědnost

7. Řádné postupy v oblasti výzkumu

8. Šíření a využívání výsledků

9. Veřejný závazek

10. Nediskriminace

11. Systém hodnocení

12. Nábor

13. Nábor (Kodex)

14. Výběr

15. Transparentnost

16. Hodnocení zásluh

17. Změny v časovém pořadí životopisů

18. Uznávání zkušeností s mobilitou

19. Uznávání kvalifikace

20. Služební věk

21. Jmenování Post doktorandů

22. Uznávání profese

23. Výzkumné prostředí

24. Pracovní podmínky

25. Stabilita a stálost zaměstnání

26. Financování a mzdy

27. Rovnováha mezi pohlavími

28. Rozvoj kariéry

29. Hodnota mobility

30. Přístup k odbornému poradenství

31. Práva duševního vlastnictví

32. Spoluautorství

33. Výuka

34. Stížnosti a odvolání

35. Účast v rozhodovacích subjektech

36. Vztahy s dohlížejícími osobami

37. Povinnosti spojené s kontrolou a řízením

38. Nepřetržitý profesní rozvoj

39. Přístup ke vzdělávání a nepřetržitému rozvoji výzkumníků

40. Kontrola

O výsledcích dotazníkového šetření a připravovaných opatření pro akční plán byli výzkumní pracovníci CPS informováni na společném setkání s vedením CPS (12. prosince 2018). Výzkumní pracovníci se zúčastňují a budou dále zúčastňovat vzdělávacích aktivit v oblasti strategického řízení výzkumné organizace, v oblasti personalistiky a principů Open, Transparent, Merit Based Recruitment (OTM-R), v oblasti finančního managementu, v oblasti zvyšování kvality a konkurenceschopnosti doktorandů ve vědě a výzkumu, v oblasti zvyšování znalostí post-doktorandů a mladých výzkumných pracovníků (do 5 let) za účelem jejich osobního a profesního rozvoje.

Prvními kroky řešení implementace HRS4R je zpracování strategií a metodických materiálů pro podporu doktorandů, kariérní řád výzkumných pracovníků, hodnocení výzkumných pracovníků, zastoupení žen ve výzkumu a vývoji, vnitřní hodnocení výzkumné organizace, mezinárodní spolupráci ve výzkumu a vývoji a internacionalizaci výzkumné organizace, mezisektorovou spolupráci v oblasti přenosu znalostí z výzkumného prostředí do praxe, popularizaci výzkumu a vývoje.

Dále bude postupně řešeno 14 opatření z Akčního plánu včetně OTM-R opatření. Pro řešení jednotlivých opatření jsou ustaveny pracovní týmy, v nichž jsou zastoupeni výzkumní pracovníci CPS.

Vnitřní hodnocení původní gap analýzy, hodnocení postupu plnění jednotlivých opatření Akčního plánu a aktualizace opatření Akčního plánu – dva roky po získání ocení, březen 2021.

Vnější hodnocení gap analýzy a postupu plnění opatření Akčního plánu za účasti hodnotitelů EK – tři roky po vnitřním hodnocení, březen 2024.

Výzkumní pracovníci jsou průběžně informováni o řešení projektu prostřednictvím webové stránky CPS, webové stránky UTB, FB CPS, hromadného e-mailu zaměstnanců CPS, prostorů CPS (InfoPoint, postery, zdi, schodiště), tiskovin (Universalia, Zlínský deník, odborný časopis).

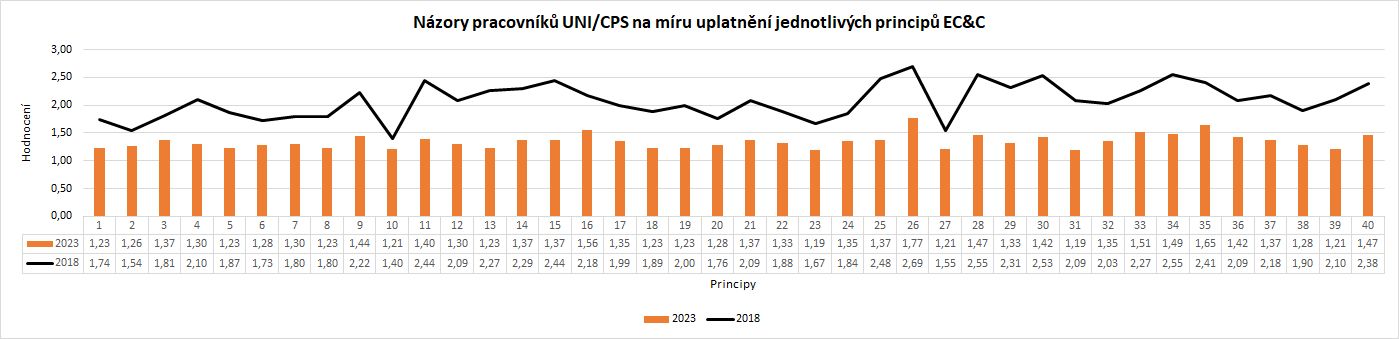

Dotazníkové šetření probíhalo v termínu od 13.10.2023 do 31.10.2023. Dotazník byl přístupne online a odkaz na něj byl rozeslán emailem. Odpovědělo celkem 43 respondentů. Výsledky dotazníku se bude zabývat pracovní skupina HR, která navrhne další postup.

Legenda ke grafu Názory pracovníků UNI/CPS na míru uplatnění jednotlivých principů EC&C.

Pro vyjádření názoru použili respondenti čtyřbodovou hodnotící škálu 1 až 4, kde: 1 = princip plně uplatněn, 2 = princip skoro, ale ne plně uplatněn, 3 = princip částečně uplatněn, 4 = princip nedostatečně uplatněn.

Jednotlivé položky:

1. Svoboda výzkumu

2. Etické zásady

3. Profesní odpovědnost

4. Profesní přístup

5. Smluvní a zákonné povinnosti

6. Odpovědnost

7. Řádné postupy v oblasti výzkumu

8. Šíření a využívání výsledků

9. Veřejný závazek

10. Nediskriminace

11. Systém hodnocení

12. Nábor

13. Nábor (Kodex)

14. Výběr

15. Transparentnost

16. Hodnocení zásluh

17. Změny v časovém pořadí životopisů

18. Uznávání zkušeností s mobilitou

19. Uznávání kvalifikace

20. Služební věk

21. Jmenování Post doktorandů

22. Uznávání profese

23. Výzkumné prostředí

24. Pracovní podmínky

25. Stabilita a stálost zaměstnání

26. Financování a mzdy

27. Rovnováha mezi pohlavími

28. Rozvoj kariéry

29. Hodnota mobility

30. Přístup k odbornému poradenství

31. Práva duševního vlastnictví

32. Spoluautorství

33. Výuka

34. Stížnosti a odvolání

35. Účast v rozhodovacích subjektech

36. Vztahy s dohlížejícími osobami

37. Povinnosti spojené s kontrolou a řízením

38. Nepřetržitý profesní rozvoj

39. Přístup ke vzdělávání a nepřetržitému rozvoji výzkumníků

40. Kontrola

Obhajoba HR Award EC měla dva kroky:

Byla ustanovena pracovní skupina pro přípravu obhajoby:

Pracovní skupina se sešla dne 30. 08. 2023 (Zápis).

Pracovní skupina se sešla dne 05. 02. 2024 (Zápis)

Pracovní skupina se sešla dne 24. 10. 2024 (Zápis, prezentace)

Pracovní skupina se sešla dne 07. 04. 2025 (Zápis, příloha)

Pracovní skupina se sešla dne 15. 05. 2025 (Zápis)

Pracovní skupina se sešla dne 02. 09. 2025 (Zápis)

ÚSPĚŠNÁ OBHAJOBA HR EXCELLENCE IN RESEARCH AWARD

Pracovní skupina se sešla dne 29. 09. 2025 (Zápis)

PŘECHOD NA REVIDOVANOU CHARTU (dostupná: https://eur-lex.europa.eu/legal-content/CS/TXT/?uri=CELEX:32023H01640 )

Pracovní skupina se sešla dne 10.02.2026 (Zápis)

Příprava Akčního plánu na další období

19.02.2026 Seminář Filtrační masterclass

10.02.2026 Setkání pracovní skupiny HR (zápis)

05.02.2026 Kolegium CPS (zápis č.1)

05.02.2026 Gumference

04.02.2026 Vyhlášena vnitřní soutěž na podporu mezinárodní spolupráce pro rok 2026 (Vyhlášení, interní komise, bližší informace)

19.12.2025 školení POKROK: Aspekty kulturních diferencí ve vzdělávacím procesu

19.12.2025 školení POKROK: Integrace zahraničních studentů a pracovníků a interkulturní komunikace

18.12.2025 Kolegium CPS a setkání zaměstnanců

15.12.2025 školení POKROK: Nové trendy v oborech - Nanotechnologie a pokročilé materiály

12.12.2025 školení POKROK: Vnímání kulturních hodnot a adaptace na nové prostředí přijíždějících studentů a akademiků

9.12.2025 Hybrid workshop on Next Generation Li-ion Batteries

4.12.2025 Studentská vědecká konference IGA

1.12.2025 Vydání nových vnitřních norem:

- PŘ/03/2025 Pravidla pro odměňování pracovníků v rámci motivačního programu pro zvyšování kvality UNI

- PŘ/04/2025 Úhrada nákladů spojených s publikacemi

- RŘ/03/2025 Výše základu pro odměňování v rámci motivačního programu pro rok 2025 na Univerzitním institutu

13.11.2025 Odborný workshop -Transfer technologií na UTB ve Zlíně

06.11.2025 Kolegium CPS (zápis)

3.11.2025 Vydání nových vnitřních norem:

- RŘ05/2025 – Prodloužení platnosti osobních příplatků

- RŘ04/2025 – Stanovení koeficientů pro osobní ohodnocení

21.10.2025 Webinář: Duševní vlastnictví a jeho právní ochrana - praktické příklady řešené na CTT

09.10.2025 Webinář: An Invisible Threat On and Off the Roads

06.10.2025 Kolegium CPS (zápis)

29.09.2025 Setkání pracovní skupiny HR (zápis)

26.09.2025 Noc vědců

25.09.2025 Obdržen EC Consensus Report Renewal Assessment

22.09.2025 HR Excellence in Research Award SITE VISIT

04.09.2025 Školení Aspekty kulturních diferencí ve vzdělávacím procesu

04.09.2025 Kolegium CPS (zápis č. 6, příloha)

02. 09. 2025 Setkání pracovní skupiny (Zápis)

08.07.2025 Přednáška Optical temperature sensing materials; The photoluminescence properties of rare-earth doped nanophosphors; The effect of alkali-metal codoping on photoluminescence properties phosphors

27.06.2025 Přednáška Tissue engineering: where are we now; The mystery of aging

25.06.2025 Přednáška The alarming situation with antibiotic resistance. Is there a light at the tunnel? Gene therapy – between dreams and reality

24.06.2025 Přednáška Challenges and successes in the fight against cancer; The challenges of viruses in the 21st century; Human microbiome

23.06.2025 Přednáška Green Routes of Vulcanization of Synthetic Rubber: A Step towards Sustainability

17.06.2025 Předprázdninová vycházka

17.06.2025 Mise, vize, strategie

17.06.2025 Etický kodex

16.06.2025 Kolegium CPS (zápis)

15.05.2025 Setkání pracovní skupiny HR (zápis)

13.05.2025 & 15.05.2025 Přednášky odborníků z eMarie Curie-Sklodowska University, Lublin, Polsko

29.04.2025 Přednášky odborníků z Mapúa University, Filipíny

25.04.2025 Kolegium CPS (zápis)

07.04.2025 Setkání pracovní skupiny HR (zápis)

03.04.2025 Deadline pro podávání návrhů GA ČR

01.04.2025 Webinář “Sustainable battery manufacturing - link

24.03.2025 Výběrové řízení pro výukové pobyty v rámci programu Erasmus+ pro akademický rok 2025/2026

12.03.-14.03.2025 Volby do Akademického senátu

12.03.2025 Kolegium CPS (zápis)

10.03.2025 Představení kandidátů do Akademického senátu UTB

28.02.2025; 05.03.2025 Semináře s předsedou Grantové agentury ČR

28.02.2025 Školení Grafický vektorový editor Inkscape

12.02.2025 Kolegium CPS (zápis)

11.02.2025 Women in Science & Research: Voices from Far That Bring Strength and Overcoming

06.02.2025 Gumference

30.01.2025 Představení nové organizační struktury související se sloučením Univerzitního institutu a Centra polymerních systémů

16.01.2025 Setkání akademických pracovníků a studentů nepříslušející k žádné z fakult UTB

09.01.2025 Kolegium CPS (zápis)

Vyhlášena soutež Podpora mezinárodní spolupráce pro rok 2025

12.12.2024 Etický kodex

12.12.2024 Mise, vize, strategie

12.12.2024 Setkání zaměstnanců

12.12.2024 Kolegium CPS

29.11.2024 Setkání akademických pracovníků a studentů nepříslušející k žádné z fakult UTB

19.11.2024 Webinář Komercialiazce výsledků výzkumu a vývoje z právního a ekonomického pohledu

31.10.2024 Kolegium CPS (zápis)

22.10.2024 Webinář Využití informací - nezbytná podmínka úspěšnosti výzkumu a vývoje i transferu technologií

15.10.2024 Webinář Influencing Lifetime of Rubber

10.10.2024 Webinář Práce s repozitářem Zenodo

27.9.2024 Seminář Etika výzkumu na UTB

1.8.2024 Kolegium CPS (zápis)

11.7.2024 Kolegium CPS (zápis)

30.6.2024 Deadline Falling Walls Lab

12.6.2024 Workshop Moodle - studentská náštěnka

12.6.2024 Deadline pro Western Balkan - Visegrad Fellowships

5.6.2024 Seminář Etický kodex

5.6.2024 Seminář Mise, vize, strategie

5.6.2024 Kolegium CPS (zápis)

23.5.2024 Deadline pro Dodatečnou vnitřní soutež Podpora mezinárodní spolupráce na rok 2024

22.-23.5.2024 Webinář Understanding & Shaping the Business Innovation - Business Modellung & Use Cases for Batteries

21.5.2024 Seminář AZV k nové soutěži VES 2025

14.5.2024 Proces nákupu na UTB

2.5.2024 Kolegium CPS (zápis)

29.4.2024 Školení Jak pracovat se studenty v akutní krizi

4.4.2024 Kolegium CPS (zápis)

27.3.2024 Online COST Info Day

21.3.2024 Science café - Lék na rakovinu: Fikce nebo realita?

14.3.2024 Seminář k projektové výzbě RP CPS 2024+

7.3.2024 Kolegium CPS (zápis)

12.3.2024 Webinář Fabrication of Battery Electrodes and Assembly

7.3.2024 Workshop CZARMA - Obnova HR Excellence in Research Award

28.2.2024 Vyhlášení výsledků voleb řádných zástupců akademických pracovníků a studentů s příslušností k Univerzitnímu Institutu

26.2.024 Workshop Introduction to techno-economic assessments

16.2.2024 Zveřejnění kandidátní listiny pro volby řádných zástupců akademických rpacovníků a studentů s příslušností k Univerzitnímu institutu

1.-15.2.2024 Možnost kandidovat do voleb řádných zástupců akademických rpacovníků a studentů s příslušností k Univerzitnímu institutu

8.2.2024 Gumference 2024

8.2.2024 Kolegium CPS (zápis)

23.2.2024 Seminář s předsedou Grantové agentury České republiky

31.1.2024 Webinář How to Do Research adn Get Publisher Webinar Series

29.1.2024 Deadline pro Erasmus + školení zaměstnanců UTB v zahraničí v akademickém roce 2024/2025

24.1.2024 Webinář Life Cycle Costing of Batteries, challenges and outlooks

24.1.2024 Setkání akademických pracovníků a studentů Univerzitního institutu

24.1.2024 Setkání zaměstnanců - představení konceptu rozvojových projektů pro následující období.

Revidovaná Charta a Kodex výzkumných pracovníků

Rada EU přijala 18. 12. 2023 „Doporučení o evropském rámci pro přilákání a udržení výzkumných, inovačních a podnikatelských talentů v Evropě“. Jeho součásti je i revidovaná Evropská charta pro výzkumné pracovníky.

Vyhlášená Interní soutěž Podpora mezinárodní spolupráce na rok 2024

Cílem projektu je vytvořit standardní evropské výzkumné prostředí pro výzkumné pracovníky CPS UTB ve Zlíně.

Výstupem projektu je návrh a implementace strategického řízení výzkumného centra orientovaný na vedení a rozvoj lidských zdrojů – Human Resources Strategy for Researchers (HRS4R). Řešení projektu je spojeno se získáním ocenění Human Resources Exellence in Research Award (HR Award), které je udělováno Evropskou komisí (EK) těm výzkumným organizacím, které splňují zásady standardního chování v evropském výzkumném prostoru. Standard chování v evropském výzkumném prostředí je definován ve čtyřiceti principech stanovených v Evropské chartě pro výzkumné pracovníky a v Kodexu chování pro přijímání výzkumných pracovníků (EC&C). Získání certifikátu EK "HR Excellence in Research award" je formálním kvalifikačním znakem příslušnosti výzkumné organizace ke společenství organizací, které sdílejí evropský výzkumný prostor umožňující efektivní komunikaci, kooperaci, mobilitu, ale také financování výzkumu, vývoje a inovací zajišťujícího další ekonomický a společenské rozvoj a konkurenceschopnost zemí EU.

Zpracování návrhu a implementace HRS4R vychází z analýzy současného stavu v uplatnění principů EC&C v podmínkách CPS UTB, identifikace slabých míst (GAP analýza) a přípravě akčního plánu opatření k postupnému dosažení standardů stanovených v EC&C. Realizace opatření v podmínkách CPS UTB povede ke změně v pojetí řízení personálu, nastavení strategické roviny řízení výzkumného centra orientované na vedení a rozvoj lidských zdrojů, ale také formování firemní kultury orientované na přijetí a sdílení hodnot, principů a zásad chování v souladu s EC&C.

Obhajoba HR Excellence in Research award EC měla dva kroky:

Byla ustanovena pracovní skupina pro přípravu obhajoby:

Pracovní skupina se sešla dne 30. 08. 2023 (Zápis).

Pracovní skupina se sešla dne 01. 12. 2023 (Zápis, Příloha 1, Příloha 2).

Pracovní skupina se sešla dne 05. 02. 2024 (Zápis)

Pracovní skupina se sešla dne 24. 10. 2024 (Zápis, prezentace)

Pracovní skupina se sešla dne 07. 04. 2025 (Zápis, příloha)

Pracovní skupina se sešla dne 15. 05. 2025 (Zápis)

Pracovní skupina se sešla dne 02. 09. 2025 (Zápis)

Pracovní skupina se sešla dne 29. 09. 2025 (Zápis)

Příprava dotazníkové šetření

Příprava Akčního plánu na další období

CPS UTB mělo jeden rok na vypracování interní gap analýzy, která má za úkol porovnat současnou praxi na CPS UTB s principy stanovenými v Evropské chartě pro výzkumné pracovníky a v Kodexu chování pro přijímání výzkumných pracovníků. Součástí gap analýzy proběhla dotazníková šetření a focus groups. Výsledkem celého procesu analýzy je akční plán, na základě kterého bude následně probíhat implementace opatření směřujících k naplnění těchto principů.

Termín

01-09/2018

03/2018

05/2018

06-09/2018

Termín

po získání ocenění HR Excellence in Research award

2 roky po získání ocenění

3 roky po vnitřním vyhodnocení (22. ZÁŘÍ 2025)